Calibration Methods

Calibration methods are essential techniques used to ensure the accuracy and reliability of measurement instruments and equipment across various industries. These methods involve comparing the readings or output of a device with known standards or reference materials to adjust and validate its performance. Calibration is crucial for maintaining the quality of measurements and meeting regulatory requirements. Common calibration methods include the use of calibration standards, reference materials, and calibration curves. In the case of instruments like thermometers, pressure gauges, and scales, calibration involves adjusting the device to match known reference points or values. Advanced calibration techniques may involve multi-point calibrations, where measurements are taken at several different levels or conditions to account for non-linearities and errors in the instrument's response. Calibration can be performed using manual procedures or automated systems, depending on the complexity of the instrument and the desired level of precision. Traceability, ensuring that calibration standards are themselves calibrated to recognized national or international standards, is essential for establishing the accuracy and reliability of calibration results. Regular calibration intervals are established based on factors such as instrument stability, usage frequency, and manufacturer recommendations to maintain measurement accuracy over time. Calibration certificates documenting the results of calibration procedures are provided to demonstrate compliance with quality standards and regulatory requirements. Calibration laboratories accredited by relevant organizations, such as ISO/IEC 17025, provide traceable and reliable calibration services for a wide range of instruments and equipment. Overall, calibration methods play a crucial role in ensuring the accuracy, reliability, and traceability of measurements, thereby supporting quality assurance, product conformity, and regulatory compliance in various industries.

Hossam A Gabbar

Ontario Tech University, Canada

Victor John Law

University College Dublin, Ireland

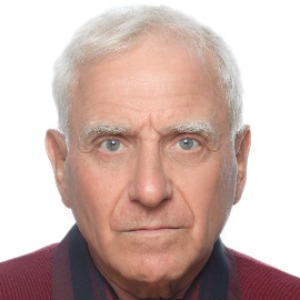

Alexander Bagaturyants

National Research Nuclear University MEPhI, Russian Federation

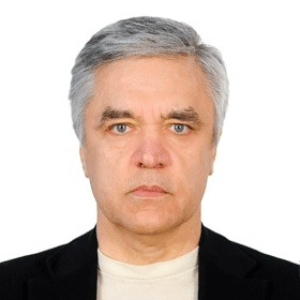

Sergey Suchkov

N.D. Zelinskii Institute for Organic Chemistry of the Russian Academy of Sciences, Russian Federation

Shree Niwas Chaturvedi

Centre for Aptitude Analysis and Talent Search, India

Pieter Samyn

SIRRIS, Belgium

Title : Advances in plasma-based radioactive waste treatment

Hossam A Gabbar, Ontario Tech University, Canada

Title : Unraveling the ultrastructure and functions of the neuronal membrane skeleton using super-resolution fluorescence microscopy

Zhou Ruobo, Djillali Liabes University of Sidi Bel Abbes, Algeria

Title : Solar box cooker dehydration, and relative humidity endpoint detection, of lamiaceae culinary leaves on the island of Crete

Victor John Law, University College Dublin, Ireland

Title : Nutrient and heavy metal loads from the Ribeiras to Coastal zones: A land-ocean continuum perspective in Madeira Island

Aracelis Del Carmen Narayan Rajnauth, University of Porto, Portugal

Title : Prospective polyoxometalate-based covalent organic framework heterogeneous catalysts

Arash Ebrahimi, Comenius University Bratislava, Slovenia

Title : Eliminating implant failure in humans with nano chemistry: 30,000 cases and counting

Thomas J Webster, Brown University, United States